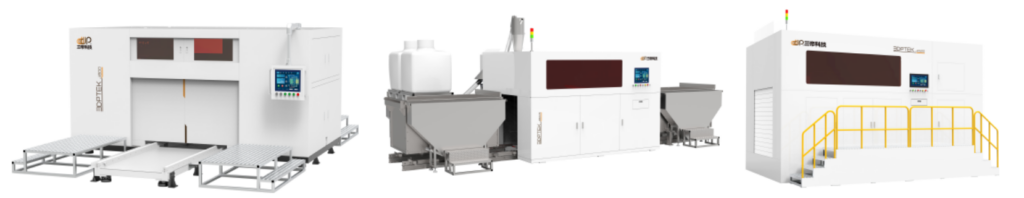

Figure: SANTI TECHNOLOGY 4 meters 3DP casting sand printer 3DPTEK-J4000

Equipment order hotline: 13811566237

For aerospace, electric energy, heavy machinery and other fields in the manufacture of ultra-large castings in the long-standing problems of long production cycle, high cost of molds, complex structure molding difficulties, 3DPTEK-J4000 with a number of innovative technologies to provide solutions:

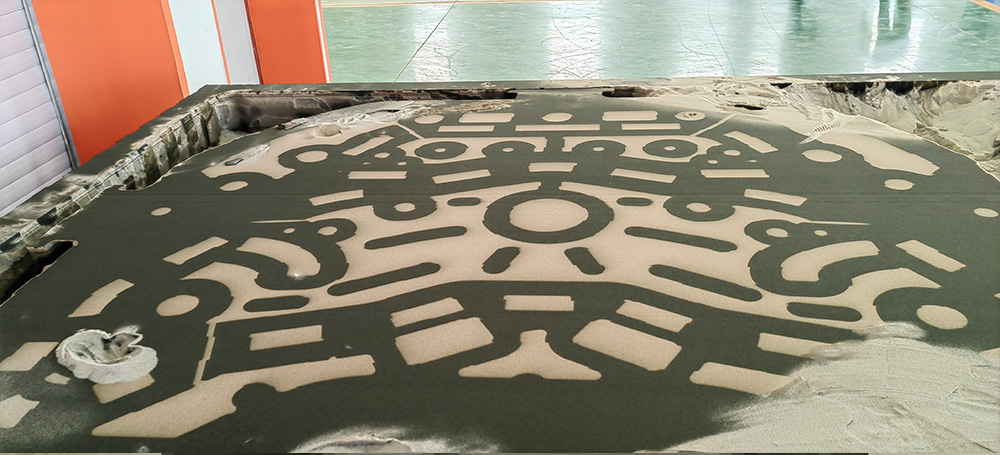

Its innovative "no sand box flexible area molding technology" not only breaks through the size limitations of traditional casting, supporting a maximum of 4 meters of sand integrated manufacturing, but also to achieve a very competitive cost control.

This technology, combined with high-precision nozzle and intelligent algorithms, can realize the integral molding of thin-walled, multi-dimensional curved surfaces and complex cavities (such as the spiral cooling water channel) of large components, solving the efficiency, cost and welding defects arising from the traditional process of making large parts that require segmental casting and then welding. Practical application shows that the technology can make large and complex castings to shorten the production cycle of more than 50%, for example, will weigh 1 ton of aluminum alloy castings delivery time from 60 days to 15 days compressed significantly.

The company also provides open-source material process system, which can be adjusted according to the user's needs; supporting high-performance resin binder, curing agent, cleaning agent, to ensure the quality and stability of molding.

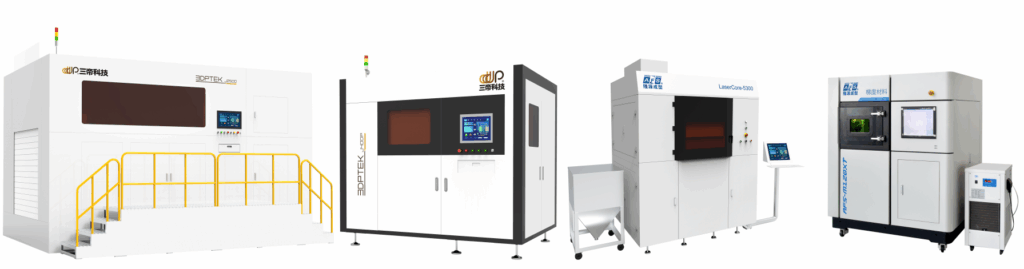

Based on 30 years of accumulation of powder laying technology, SANDI Technology has independently developed full-size 3DP casting sand and SLS casting sand/wax series printers from millimeters to meters, which can satisfy the manufacturing needs of products of different sizes and materials, and help users maximize their productivity with lower unit cost and shorter delivery time.

Figure: SANDY TECHNOLOGY 3DP Casting Sand Printer 3DPTEK-J1800/J1800S/J2500

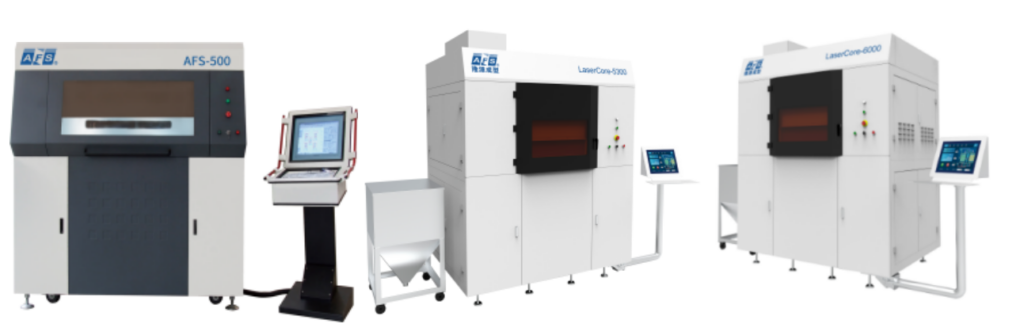

Figure: SANDY Technology SLS Casting Sand/Wax Printer AFS-500/LaserCore-5300/LaserCore-6000

The honor of being on the list of 2025 additive manufacturing quality products is a full affirmation of SanDi Technology's adherence to independent innovation and deepening of the path of industrialization. Starting from 3D printing, upgrading manufacturing with digital technology. In the future, SANDI Technology will continue to help more manufacturing enterprises realize quality and efficiency improvement and transformation and upgrading through its leading equipment, materials and full chain service capabilities, and contribute to the development of new quality productivity.

[About SANDI TECHNOLOGY

(3D Printing Technology, Inc.) is a national high-tech enterprise and a "small giant" enterprise specializing in industrial-grade additive manufacturing (3D printing) equipment and rapid manufacturing services. The company has built a complete industrial chain covering technology research and development, equipment and material production, process support and manufacturing services, and is in a leading position in a number of core technologies such as binder jetting (BJ/3DP) in China, and is actively promoting the large-scale application of 3D printing in the fields of casting upgrading, advanced heat dissipation, and precision medical care.

]]>喜報!欣鑫鑄造5N超高純鋁制備項目獲批陜西省重點產業鏈關鍵核心技術產業化“揭榜掛帥”支持最先出現在三帝科技股份有限公司。

]]>

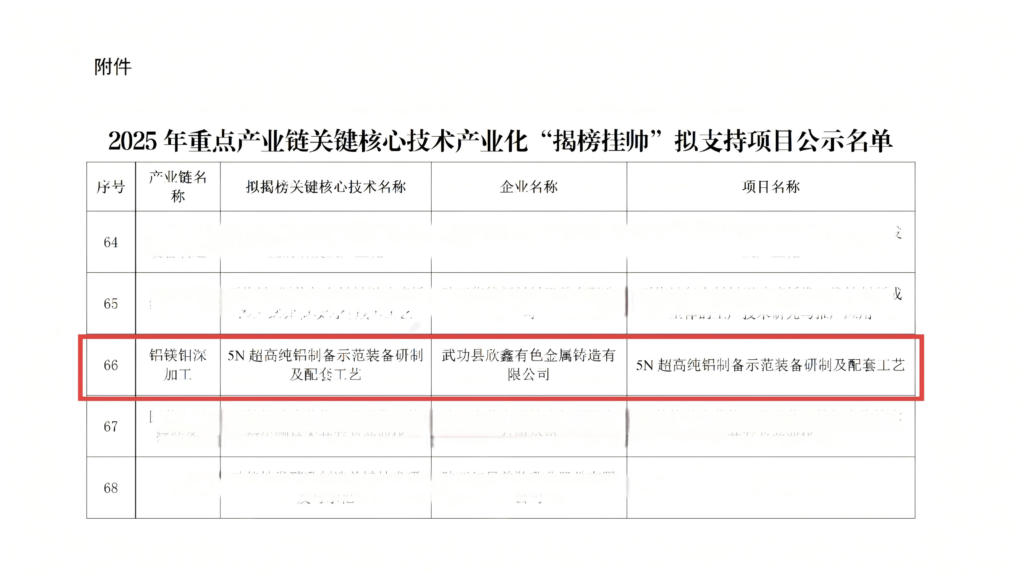

Recently, a subsidiary of Beijing SANDI Technology Co.Wugong Xinxin Nonferrous Metal Casting Co.(The project of "5N Ultra High Purity Aluminum Preparation Demonstration Equipment Development and Supporting Processes" jointly declared by Xinxin Foundry (hereinafter referred to as Xinxin Foundry) and Xi'an University of Technology (hereinafter referred to as Xi'an University of Technology) was successfully selected as one of the key core technology industrialization projects to be supported by Shaanxi Province in 2025 (hereinafter referred to as the Project). The project "Development of 5N Ultra-high-purity Aluminum Preparation Demonstration Equipment and Supporting Process", jointly declared by Xi'an University of Technology (XUT) and Xi'an University of Technology (XUIT), has been successfully selected as one of the projects to be supported by "Unveiling and Hanging" for the industrialization of key core technologies of key industrial chains in Shaanxi Province in 2025. The program aims to promote the industrialization of key core technologies by targeting and deploying key core technology research and development for the short boards of key industrial chains through the method of "unveiling the list of commander-in-chief".

Ultrahigh-purity aluminum (purity ≥ 99.999%) is a key basic material indispensable to high-end manufacturing fields such as semiconductor integrated circuits, solar cells, aircraft navigation systems, radar and so on. Due to its preparation technology barriers are extremely high, for a long time, the material preparation technology is monopolized by foreign countries, China's demand is highly dependent on imports, has become a prominent short board of the industrial chain security.

The unveiled project aims to research and develop complete sets of preparation technology and demonstration equipment for ultra-high purity aluminum above 5N level with complete independent intellectual property rights, aiming to build a demonstration production line with an annual output of 30 tons, and to realize that the key indexes such as material purity, product size, production efficiency and energy consumption and environmental protection have reached the international advanced level.

The project proposes a new process of "melt multi-field coupling solidification regulation multi-link integration of fine aluminum preparation", which aims to realize efficient, low-consumption and green preparation of large-diameter ultra-high-purity aluminum ingots by integrating the synergistic effect of ultrasonic field, electromagnetic field, temperature field and other physical fields. The core technology of the project has three major innovations:

1. Engineering efficient purification methods and equipment. Achieve axial high gradient and radial balanced temperature field control of ultra-high purity aluminum ingot with diameter 50-160mm, and the comprehensive removal efficiency of impurities is increased to 80%.

2. Multi-field coupling integrated process. Technically replace the traditional electrolysis method and establish a fully automated production process route with low energy consumption and low pollution.

3. Frontier mechanism research. In-depth revelation of the changing law of solute boundary layer under rotating magnetic field, providing theoretical support for process optimization.

The project is implemented by Xinxin Casting as the main body of industrialization, and Xi'an University of Technology provides cutting-edge technology research and theoretical support, which is a model of the deep integration of "industry, academia, research and application". Xinxin Casting gives full play to its own rich experience and engineering capabilities in non-ferrous metal melting, casting, precision machining and industrialization, and Xi'an Polytechnic University to form a strong alliance with the top scientific research strength in materials science, solidification theory and other aspects.

As a high-tech enterprise focusing on the field of high-end casting and new materials under the banner of Three Emperor Technology, Xinxin Casting, relying on the strategic support of the parent company in scientific and technological innovation and industrial layout, has continued to increase investment in research and development, and has built an advanced manufacturing system covering 3DP sand printing, precision machining, and full-process testing, which lays a solid foundation for undertaking this kind of major scientific and technological research projects.

Xi'an University of Technology has profound scientific research accumulation in the fields of composite materials and solidification technology, and its research results have won the second prize of the National Science and Technology Progress Award, and the cooperation between the two sides will give full play to the advantages of each side in the engineering application and cutting-edge research.

After the successful implementation of the project, it will not only fill the blank of domestic high-end ultra-high purity aluminum scale green preparation, meet the urgent needs of semiconductor, new energy, aerospace and other industries, and bring considerable economic benefits, but also drive Shaanxi Province and even the whole country "aluminum magnesium and aluminum deep-processing" industry chain to the high-end, green upgrading.

喜報!欣鑫鑄造5N超高純鋁制備項目獲批陜西省重點產業鏈關鍵核心技術產業化“揭榜掛帥”支持最先出現在三帝科技股份有限公司。

]]>In late 2025, a handwheel on a key piece of equipment on a Norwegian oil and gas rig suddenly broke. Under the traditional model, replacement would have required a 12-month procurement cycle. But this time, engineers placed an order via a digital platform and just a few days later, a handwheel in PA12 material printed using the HP Multi Jet Fusion system was manufactured by a local service provider.

Behind this is a globalized manufacturing network of industrial 3D printing companies.

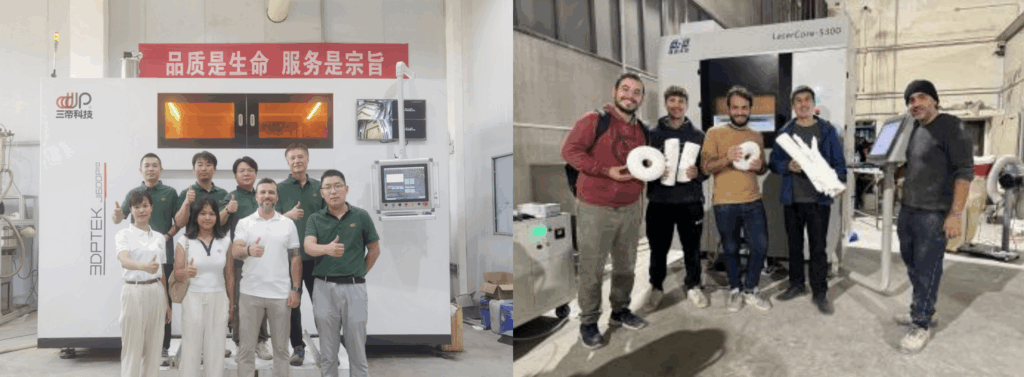

Meanwhile, on the other side of the globe, 3D printing equipment of SANDI Technology is being sent to Italy, Turkey, Spain, South Korea and other countries. This company, which has been deeply cultivating the field of industrial-grade 3D printing for dozens of years, has realized a breakthrough in the overseas market from almost zero to accounting for 15% of the company's revenue in just one year.

Photo: SANTI TECHNOLOGY's industrial-grade 3D printing equipment shipment(Source: SANTI TECHNOLOGY)

As Xia Chunguang, co-founder of MoFang Precision, said, "The more precise a part is, the higher the cost of developing and producing it in the traditional way." This is precisely the core competitiveness of Chinese industrial 3D printing companies going overseas - they not only export products, but also export a new manufacturing paradigm.

01 Industry journey: from "laboratory" to "globalization"

The global 3D printing market is witnessing explosive growth. According to Mordor Intelligence, the global 3D printing market size is expected to exceed $110 billion by 2030, growing at a CAGR of more than 36% during 2025-2030.

The regional market landscape is distinct: North America accounted for 41.681 TP3T of global spending, while Asia-Pacific is expected to expand at a CAGR of 26.471 TP3T, making it the fastest growing region.

In this wave of globalization, Chinese industrial 3D printing enterprises present a unique path to the sea.

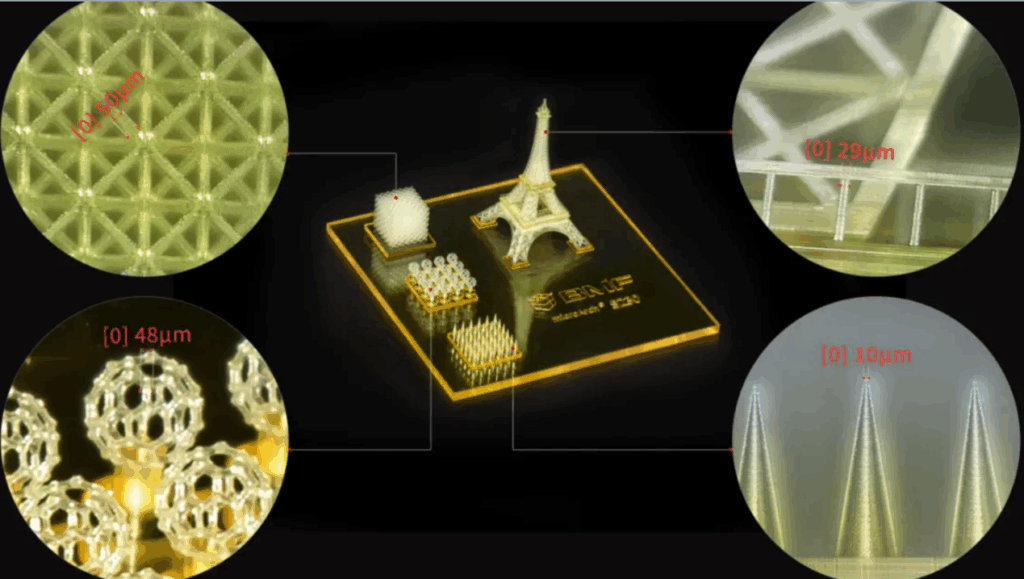

MoFang Precision's overseas experience is quite legendary. 2019, MoFang Precision displayed additive manufacturing equipment with a printing precision of up to 2 microns at an industrial exhibition in the U.S., which triggered onlookers.

Figure: Precision prototypes manufactured by Mofang Precision (source: internet data)

A foreign friend saw the print sample, one knee on the ground, close and carefully scrutinized for a long time. The breakthrough in precision allowed Mofang Precision to open up the market of developed countries.

In only 3 years, MoFang Precision has set up overseas branches in the United States, Japan, Germany, Britain and other places. In 4 years of going to sea, the products are exported to 35 countries, and the proportion of overseas sales reaches 50%.

SANDI Technology has chosen a different path. By mastering the four industrial-grade 3D printing technologies of SLS (Selective Laser Sintering), SLM (Selective Laser Melting), 3DP (Sand Printing), and BJ (Binder Jet), and exporting the equipment, SANDI TECH has precisely targeted the Eurasian market, where the demand for digital dentistry is strong and the price-performance ratio is sensitive.

Its overseas revenue soared from almost zero to $15% in a year, achieving a substantial breakthrough.

02 Path exploration: three sea lanes, four global playing styles

The paths of Chinese industrial 3D printing companies to the sea can be broadly categorized into three distinctive shipping lanes, and the success of SanDi Technology demonstrates the effectiveness of a hybrid model.

The first one is "technological conquest".

Mofang Precision relies on its self-developed "surface projection microstereolithography" technology to realize high-precision detail printing of 2 microns, and control the tolerance size in the range of +-10 microns. This technological breakthrough makes Mofang Precision the only company in the world to successfully provide high-precision additive manufacturing solutions.

Technological innovation has become the fulcrum for them to pry the global market.

Figure: Map of R&D and production of Mofang Precision equipment (Source: official website of Mofang Precision)

The second is "cost-disruptive".

Through supply chain consolidation, Intelligent Pie has been able to source display screens for light-curing 3D printing at a significantly lower price than the market price, and in 2019, they are launching the "Mars" series, which is the market's first device in the $300 range that combines 2K printing accuracy.

While the average pricing of domestic brands at the time was around $500, overseas brands were upwards of $1,000 USD.

Figure: ELEGOO DLP Light Curing 3D PrinterMARS 4 DLP (Source: ELEGOO website)

The third is "ecological networking".

Some companies have followed HP's model of building an Additive Manufacturing Network to enable localized production and rapid response by building a global manufacturing and service network, and Korall Engineering, along with partners such as HP, has achieved the ability to locally print and deliver spare parts in the oil and gas industry in a matter of days.

The fourth is a "technology + M&A hybrid".

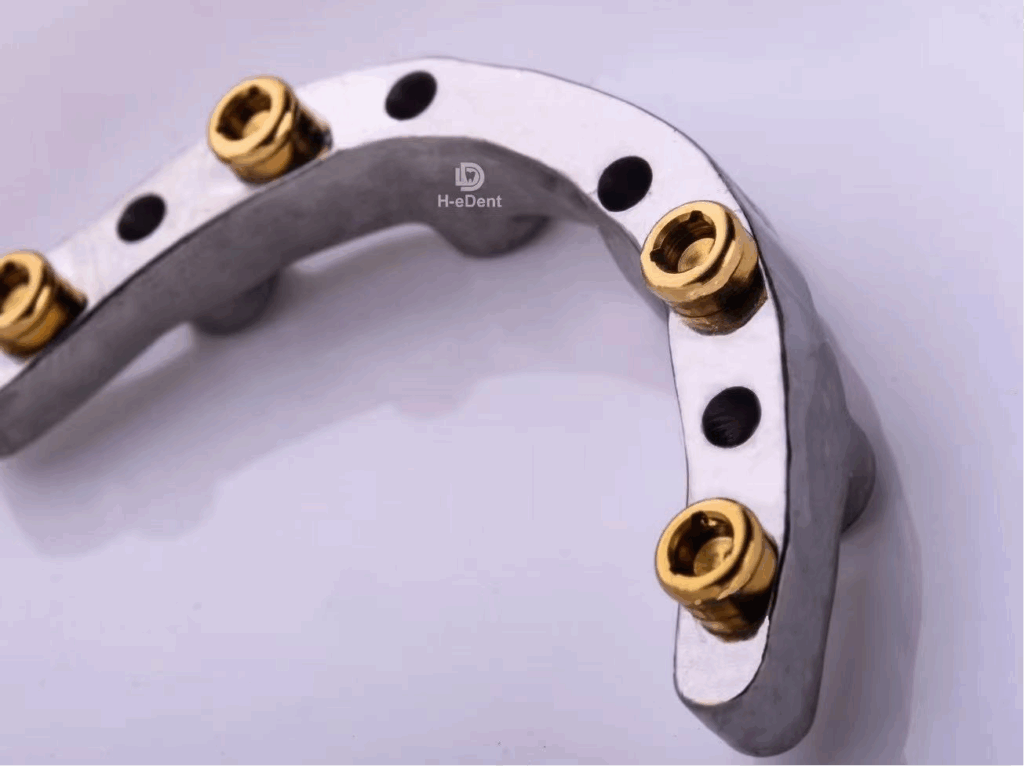

SANDI Technology has taken a unique path combining technology and mergers and acquisitions. 2025, SANDI Technology acquired Shenzhen Shuanglong Dental Research Technology Co., Ltd, a company that specializes in high-end customized dentures. This move not only allows SANDI Technology to obtain the mature channels established by Shuanglong Dental Research covering more than 30 countries and regions in the world, such as America, Europe, Australia, Southeast Asia, etc., but also take over all of its international certifications and customer resources in one go, realizing the leapfrog development of the process of going abroad.

Figure: Titanium alloy bridge (Source: Shenzhen Shuanglong Dental Research)

03 Cracking the Dilemma: Challenges and Responses on the Way to the Sea

The road of industrial 3D printing to the sea is not a smooth one, and enterprises need to face a series of challenges.

Trade barriers are the primary challenge.

Against the backdrop of the continued increase in U.S. tariff policies, China's industrial-grade 3D printer companies are facing multiple challenges such as surging export costs, supply chain restructuring and limited market access.

Certification bottlenecks should likewise not be ignored.

"Flight hardware such as turbine nozzles or pressurized valves must comply with rigorous fracture toughness and fatigue testing," reports Mordor Intelligence, "and the current rulebook is written for subtractive machining; as a result, additive parts undergo redundant sample testing, extending schedules by as much as 18 months."

In this regard, through the merger and acquisition of Shuanglong Dental Research, SanDi Technology has obtained the European Union CE, U.S. FDA and China's Class II medical device certification, paving the way for products to travel the international market.

Intellectual property risks follow.

As a technology-intensive industry, 3D printing companies face a complex IP environment, especially in mature markets in Europe and the United States.

In the face of these challenges, companies that have successfully gone overseas have adopted a variety of coping strategies.

Localization of supply chain layout is an effective means to deal with trade barriers. The study suggests that Chinese enterprises can optimize global capacity allocation through the distributed layout model of "regional manufacturing centers + localized manufacturing units".

SANDI has implemented lean management in all aspects of production to ensure the reliability and consistency of product quality. In addition, the company has reached strategic cooperation with a number of international high-quality logistics service providers to customize safe and efficient transportation solutions for each order, fully guaranteeing the timeliness and integrity of global equipment output.

Internationalization of technical standards is the key to break through the certification bottleneck. Mofang Precision's innovative ability has been recognized by the Prism Award, an authoritative award in the global optoelectronic science and technology industry, and in March 2021, Mofang Precision became the first company in China to win the award, beating two well-known U.S.-listed companies.

Market diversification is a strategic choice to diversify risks. Intelligent Pie Europe and the United States users accounted for 92%, but at the same time also sell products to more than 70 countries and regions around the world.

SANDI Technology, on the other hand, has accurately cut into high-growth markets such as Turkey and Spain. In Turkey, for example, the scale of its dental industry is expected to reach 5 billion U.S. dollars in 2025, dental tourism contributes 70% share, of which the 3D printing denture equipment orders increased year-on-year up to 55%, the market opportunity is huge.

04 Future strategy: from "product to sea" to value to sea

As the global 3D printing market continues to mature, Chinese companies are upgrading their overseas strategies.

Supply chain strategy is shifting from pure export to global capacity placement.

"Regionalized production networks" and "technology localization strategies" have become important means of coping with changes in the global trade environment. Some leading companies have begun to strategically locate in emerging economies such as Southeast Asia, Central and Eastern Europe, and Latin America.

Technology development is showing a diversification trend.

Metal 2 micron high precision detail printing, and control the tolerance size in the range of +-10 micron, +-25 micron respectively.

Some of SANDI Technology's early equipment has been in continuous and stable operation for more than 20 years, which has earned it a very high level of trust in the market. The four core 3D printing technologies it has mastered can provide the mature technical assurance required for diversified manufacturing needs.

Market expansion extends from developed countries to emerging markets.

Asia Pacific has become the fastest growing region in the global 3D printing market, with the Chinese government's "Made in China 2025" policy driving the growth of local companies.

The business model has also evolved from single device sales to diversification.

Some organizations have begun to offer "print-by-the-hour" subscription services that combine maintenance, calibration and powder replenishment into a single invoice. This hybrid approach blurs the line between hardware and services, smoothing out revenue streams during macroeconomic cycles.

05 Future Outlook: From "Manufacturing to Overseas" to "Ecological Overseas"

The next stage of industrial 3D printing overseas will be the shift from product output to the construction of a global digital manufacturing ecosystem.

The digital supply chain is becoming a core competency.

Korall Engineering's approach heralds this trend - they identify key components, model modular systems, and automate the derivation of variants. These data sets are then made available to certified manufacturing partners via Korall's own Oktopus platform.

The transformation of servitization has become a value growth point.

The 3D printing services market is expected to outpace the hardware market at a CAGR of 25.21% from 2025 to 2030.Contract manufacturers such as Stratasys Direct Manufacturing, Materialise, and Protolabs utilize multi-site networks to distribute loads, allow customers to prototype in ten days and receive parts that meet ISO-13485 production standards.

A global collaborative network will be the ultimate form.

HP is connecting part requirements with its partner network through its Additive Manufacturing Network program. Similarly, Korall has partnered with HP, Assembrix and Sparely to implement a series of secure remote printing jobs.

Dozens of industrial-grade granular 3D printers are working 24/7 in an intelligent factory in Zhuhai. They are printing automotive parts and consumer products of different specifications according to orders from customers in Europe and North America.

On the workshop's electronic screen, a global production status map flashes in real time, marking manufacturing nodes spread across continents.

At the same time, SANDI's shipment list continues to grow with orders from Italy, Turkey, Spain and South Korea, witnessing the transformation of China's industrial 3D printing from technological catch-up to global leadership.

Zong Guisheng, founder of SANDI Technology, believes that from technological breakthroughs to global layout, we are redefining the position of Chinese manufacturing in the global industrial chain.

His eyes are reflecting the new chapter of China's industrial 3D printing overseas - that is not only the flow of products, but also the manufacturing paradigm, technical standards and industrial ecology of global integration. (Source: Zongguancun Public)

The 7th Asia Powder Metallurgy International Conference & Exhibition (APMA2025) was successfully held from October 19 to 22, 2025 in Qingdao, Shandong Province. Co-organized by the Powder Metallurgy Industry Technology Innovation Strategy Alliance (CPMA) and the Chinese Society for Metals (CSM), the conference brought together top experts and enterprise representatives in the field of powder metallurgy from home and abroad. BJ Binder Jet Metal/Ceramic Printer independently developed by SANDY Technology3DPTEK-J400PDr. Zong Guisheng, Director of 3D Printing Committee of Powder Metallurgy Industry Technology Innovation Strategy Alliance and Chairman of SANDI Technology, was awarded "Outstanding Contribution Award of Powder Metallurgy".

As an important participant of the conference, SANDI Technology was deeply involved in a number of agendas. Dr. Zong Guisheng served as the chairman of the Additive Manufacturing sub-forum of the conference and gave an invited report on "BJ Binder Jetting Manufacturing", sharing the cutting-edge practice of this technology in promoting the high efficiency and low cost of the powder metallurgy industry.

Dr. Zong Guisheng pointed out in the report that traditional powder injection molding faces pain points such as high mold costs, long development cycles and limited product sizes. Through binder jet (BJ) 3D printing technology, SANDI Technology has realized moldless manufacturing, rapid prototyping of complex structures and large-size parts production, effectively helping the industry to achieve cost reduction and efficiency. Currently, the technology has been applied on a large scale in 3C electronics, automotive, aerospace, AI chip cooling, liquid cooling system and other fields.

BJ Binder Jet Metal/Ceramic Printing System Enables Efficient Precision Manufacturing

SANDI Technology has systematically mastered a full set of key technologies of BJ binder jet metal/ceramic molding equipment, materials and processes. Its 3DPTEK-J160R/J400P/J800P series printing equipment, integrated with precise powder supply, high density powder laying and high precision inkjet control system, to effectively deal with the small particle size powder laying problems, support 400-1200dpi high-resolution printing, the highest molding accuracy of ± 0.1mm, the highest molding efficiency of 3600cc/h. The highest molding efficiency is 3600cc/h.

Figure: SANDY TECHNOLOGY BJ Binder Jet Metal/Ceramic Molding Printer 3DPTEK-J160R/J400P/J800P

In terms of material system, the company has developed more than 20 kinds of process formulations, such as water-based environmentally friendly and solvent-based high-efficiency type, covering a wide range of metal materials such as stainless steel, titanium alloy, high-temperature alloy, as well as ceramic and non-metal materials such as silicon carbide. Through systematic control of the degreasing and sintering process, the company has realized precise control of the shape and performance of the products, and the performance of the products meets and partially exceeds the international standards.

Based on the advantages of "high efficiency, low cost and no thermal stress" of BJ technology, SANDI has made important breakthroughs in the field of heat dissipation, successfully realizing the high-quality molding of copper-diamond, copper-silicon carbide and other composites, and the performance is better than the international standard of MIM. The company implements differentiated equipment strategy, for scientific research institutions and chip design enterprises, to provide scientific research equipment 3DPTEK-J160R, for rapid prototyping and thermal design verification; for liquid-cooled servers and other industrial users, to provide integrated industrial solutions (equipment + special powder / binder + process package), to help customers shorten the process development cycle of 60% or more.

SLM Laser Metal Printing Expands Technology Boundaries with Gradient Material Systems

In addition to binder jetting technology, SANDI Technology has also independently developed metal printing systems including SLM selective zone laser melting equipment AFS-M120/M400, gradient metal equipment AFS-M120X(T), and multi-material additive and subtractive material integration equipment AFS-M300XAS, etc., and completed a variety of stainless steel, titanium alloy, aluminum alloy, die steel, cobalt-chromium alloy, nickel-based alloy and other We have also completed the process development of various materials such as stainless steel, titanium alloy, aluminum alloy, mold steel, cobalt-chromium alloy and nickel-based alloy.

Among them, AFS-M120X(T) can realize the continuous gradient accurate powder supply of two or more metal materials, which is suitable for the research of composite metal material properties; AFS-M300XAS supports the gradient combination of up to four materials, and realizes the continuous gradient change in the horizontal direction, and material composition switching or gradient change in the vertical direction, which is promising for the development of high-throughput materials, aerospace, automotive, medical and mold processing, and other fields. It has broad prospects in the fields of high-throughput material development, aerospace, automotive, medical and mold processing, etc.

SANDI Technology always focuses on the synergistic development of industry, academia and research, and maintains close cooperation with Shenzhen Vocational and Technical University, Shenzhen Tsinghua University Research Institute, Shanghai Jiaotong University, University of Science and Technology of Beijing and other universities and scientific research institutes, and continues to promote the basic research and transformation of BJ technology in the materials, processes and applications, to help industrial molds, high-end cutting tools, 3C electronic precision components and complex large-size shaped ceramic products and other areas of large-scale application. The scale application of BJ technology.

[About SANDI TECHNOLOGY

SANDI Technology is a national high-tech enterprise and a "small giant" enterprise specializing in industrial-grade additive manufacturing (3D printing) equipment and rapid manufacturing services. The company has built a complete industrial chain covering technology research and development, equipment and material production, process support and manufacturing services, and is in a leading position in a number of core technologies such as binder jetting (BJ) in China, and is actively promoting the large-scale application of 3D printing in the fields of casting upgrading, advanced heat dissipation, and precision medical care.

]]>

It is reported that the 3DP sand printing equipments provided by SANDI Technology to many domestic manufacturing enterprises in Liaoning, Hebei, Henan, Jiangsu, Guizhou and other places have been sent out successfully in recent days. When the equipment arrives at the customer's site, the professional technical team of SANDI Technology will follow up the assembly, debugging and acceptance work at the first time to ensure that the equipment is put into production quickly and operates stably. At present, SANDI's equipment and services have covered 26 provinces (including autonomous regions and municipalities directly under the Central Government), widely serving the main foundry industry belt and intelligent manufacturing clusters, and continuing to provide power for the transformation and upgrading of customers.

At the same time, the overseas market expansion has achieved remarkable results. A number of 3D printing equipments sent to Korea, Turkey, Italy, France, Spain and other regions have been successfully shipped and are about to be delivered. At present, SANDI's products and services have covered many key markets in Europe and Asia, such as East Asia, South Asia, Western Europe, Eastern Europe, etc. The globalized operation system is becoming more and more perfect, showing strong international competitiveness.

With more than 30 years of experience in industrial-grade 3D printing, SANDI Technology has deep experience in powder laying technology and stable and reliable equipment. After years of market verification, the 3D printing equipment purchased by some users in the early stage of the company's business has been in stable operation for more than 20 years. The company also masters selective laser sintering (SLS), selective laser melting (SLM), sand 3D printing (3DP) and binder jetting (BJ) four core 3D printing technology, its "3DP + SLS" composite sand process has been selected by the Ministry of Industry and Information Technology of the typical application of additive manufacturing scenarios, can provide mature technical support for the diversified manufacturing needs. It can provide mature technology guarantee for diversified manufacturing needs.

In the production process, SANDI Technology comprehensively implements lean management, continuously optimizes the process of equipment assembly and commissioning, and ensures the reliability and consistency of product quality while improving production efficiency by strengthening cross-departmental collaboration and standardized on-site operations. All key components are strictly inspected and qualified before entering the assembly, realizing the whole process of quality traceability and precise control from parts to the whole machine.

In the delivery process, the company strictly implements the factory verification mechanism, the relevant person in charge checks and inspects the equipment one by one according to the "Application for Equipment Factory Permit", and carries out special marking and explanation for the customer's personalized needs, so as to ensure that the equipment is delivered accurately and in good condition. Through efficient cross-departmental collaboration and real-time information transfer, the company realizes seamless connection from production to delivery, and continues to consolidate the advantages of efficient delivery.

SANDI Technology not only provides high-performance equipment, but also focuses on full-cycle services. We provide comprehensive hands-on training and process guidance to our customers through our 3D Smart Manufacturing Centers throughout the country. Through the after-sales team in Beijing, Shaanxi, Hebei, Henan, Guangxi, Shandong, Anhui and other regions to provide timely response and nearby service, effectively guarantee the continuous and stable operation of customer equipment. At the same time, the company actively promotes market synergy and resource sharing to help customers expand business opportunities and enhance market competitiveness.

In addition, SANDY Technology attaches great importance to the professional capacity building of the team, through regular training and production coordination mechanism, to continuously improve the assembly efficiency and product quality. The company has reached strategic cooperation with a number of international high-quality logistics service providers to customize safe and efficient transportation solutions for each order, fully guaranteeing the timeliness and integrity of global equipment output.

Under the background of accelerated intelligent and digital transformation of the global manufacturing industry, SANDY Technology, relying on the three-in-one synergistic innovation system of "Guoqian Science and Technology Research Institute, post-doctoral workstation, and enterprise R&D team", continuously breaks through the key technologies, optimizes the performance of the products, and continues to improve the international marketing and service network and enhance the overseas localized service capability, to provide high-performance 3D printing equipment and rapid manufacturing integrated solutions for global customers with global vision and international standards. Global vision and international standards to provide global customers with high-performance 3D printing equipment and rapid manufacturing solutions to empower the high-quality development of the manufacturing industry.

[About SANDI TECHNOLOGY

(3D Printing Technology, Inc.) is a national high-tech enterprise and a "small giant" enterprise specializing in industrial-grade additive manufacturing (3D printing) equipment and rapid manufacturing services. It has been invested by many organizations, including Jinko Junchuang, CICC Capital, Zhongke Haichuang, Become Capital, Beijing New Materials Fund, and SINOMACH Fund, etc. The company has been invested by the Ministry of Economic Affairs of the People's Republic of China. Aiming at cost reduction, efficiency improvement and quality improvement, the company has built a complete industrial chain covering the R&D and production of 3D printing equipment and materials, process technology support and rapid finished product manufacturing. Widely served in aerospace, electric power and energy, ship pumps and valves, automotive, rail transportation, industrial machinery, 3C electronics, rehabilitation and medical care, education and scientific research, sculpture, culture and creativity and other fields.

]]>Read navigation

- Chapter 1: Deep Dive: The Root Challenge of Traditional Casting Defects

- Chapter 2: 3D Printing: A Revolutionary Breakthrough from Technology to Solution

- Chapter 3: SANTI TECHNOLOGY: A Digital Engine to Empower the Foundry Industry

- Chapter 4: Looking to the future: digitalization and sustainability in the foundry industry

Chapter 1: Deep Dive: The Root Challenge of Traditional Casting Defects

1.1 Common casting defects and their deep causes

Casting defects are the direct cause of high scrap rates. These defects are not accidental, but are dictated by the physical and process limitations inherent in conventional casting processes.

firstlystomatogether withshrinkage. Porosity mainly originates from the involvement or inability to effectively discharge gases (e.g. hydrogen, mold outgassing) in the liquid metal during the pouring and solidification process. When the dissolved gases in the liquid metal are released due to reduced solubility during cooling and solidification, bubbles will form inside or on the surface of the casting if they are not discharged in time. Related to this is shrinkage, which is a natural phenomenon of volume contraction of the metal during solidification. If the cooling system is not properly designed, resulting in local mold temperature is too high, or insufficient complementary shrinkage, it will form internal voids or depressions, the so-called shrinkage holes.

Next.sandwichedtogether witherror type (math.). In conventional sand casting, sand molds and sand cores usually need to be assembled and bonded after being made from multiple pieces separately. In this process, any tiny rupture of the sand core or improper bonding may lead to sand particles being caught in the metal liquid, forming sand entrapment defects. In addition, if the mold parting surface or the sand core is not positioned accurately, it may also lead to the casting of the upper and lower parts of the misalignment of the mis-shape defects.

endcold storagetogether withcrackles. When the fluidity of the metal liquid is poor, the pouring temperature is too low, or the runner design is narrow, the two metal streams are solidified without being fully integrated at the leading edge, leaving a weakly connected cold segregation. And during cooling and solidification, if there are uneven stresses within the casting, thermal cracks may occur during shrinkage.

1.2 The traditional mold manufacturing "high cost" and "low efficiency" dilemma

Another core pain point of the traditional casting process is its mold manufacturing process. Traditional wood or metal core box manufacturing is a labor-intensive, highly skilled worker-dependent process with long lead times and significant costs. Any minor design change means that the mold needs to be rebuilt, resulting in high additional costs and weeks or even months of waiting time.

This over-reliance on physical molds also fundamentally limits the design freedom of castings. Traditional mold-making processes are unable to mold complex internal runners and hollow structures in one piece, which must be disassembled into multiple independent sand cores and then assembled by complex tooling and labor. 2. This process limitation forces designers to compromise and sacrifice part performance for manufacturability, such as simplifying cooling channels to accommodate drilling processes that do not allow for optimal cooling.

To summarize, the high scrap rate of traditional casting is not an isolated technical problem, but a product of its core processes. The traditional "physical trial and error" mode makes the foundry in the discovery of defects, need to go through a long process of mold modification and retesting, which is a high-risk, inefficient cycle. 3D printing's revolutionary value is that it provides a "moldless" solution, fundamentally reshaping the entire production process, will be the traditional "physical trial and error" mode, will be the traditional "physical trial and error" mode, will be the traditional "physical trial and error" mode, will be the traditional "casting" high scrap rate is not an isolated technical problem, but its core process products. The revolutionary value of 3D printing is that it provides a "moldless" solution that fundamentally reshapes the entire production process, transforming the traditional "physical trial-and-error" model into a "digital simulation validation" that puts the risk in front of the process, thus eliminating most of the causes of scrap at the source.

Chapter 2: 3D Printing: A Revolutionary Breakthrough from Technology to Solution

2.1 Moldless production: eliminating the root causes of obsolescence

The core advantage of 3D printing is its "moldless" production method, which allows it to bypass all of the mold-related challenges inherent in traditional casting, thus radically reducing scrap rates.

Directly from CAD to sand mold. Binder Jetting in Additive Manufacturing is the key to making this happen. It works by precisely spraying liquid binder onto thin layers of powder (e.g. silica sand, ceramic sand) from an industrial-grade printhead based on a 3D CAD digital model. By bonding layer by layer, the 3D model in the digital file is constructed in the form of a solid sand mold or sand core. This process completely eliminates the need to rely on physical molds. Because there is no need for lengthy mold design and manufacturing, the mold-making cycle can be shortened from weeks or even months to hours or days, enabling "print-on-demand" and rapid response to design changes, dramatically reducing up-front investment and trial-and-error costs.

One-piece molding and complex structures. 3D printing's layered manufacturing approach gives unprecedented design freedom. It is able to mold complex sand cores that would traditionally have to be split into multiple parts, such as the meandering runners inside an engine, into a single monolithic piece. Not only does this simplify the casting process, but more importantly, it completely eliminates the need for core assembly, bonding and misalignment, thus eradicating common defects such as sand entrapment, dimensional deviations, and misshaping caused by such issues.

2.2 Optimization process: data to guarantee casting quality

The value of 3D printing goes beyond "moldlessness" itself. It elevates the manufacturing process to a whole new digital dimension, allowing data to be verified and optimized before physical manufacturing, turning "after the fact" into "before the fact".

Digital Simulation and Design. During the digital design phase prior to 3D printing, engineers can use advanced Finite Element Analysis (FEM) software to perform accurate virtual simulations of the pouring, make-up shrinkage and cooling processes. This makes it possible to anticipate and correct potential defects that could lead to porosity, shrinkage or cracks before actual production. For example, by simulating the flow of the liquid metal in the runners, the design of the pouring system can be optimized to ensure smooth filling and effective venting. This digital foresight greatly improves the success rate of the first trial run and guarantees casting yields at the source.

Excellent sand properties. 3D printed sand molds, due to their layer-by-layer construction, can achieve uniform densities and air permeability that are difficult to achieve with traditional processes. This is crucial for the casting process. Uniform gas permeability ensures that gases generated inside the sand mold can escape smoothly during the pouring process, significantly reducing porosity defects caused by poor venting.

Cooling with shape. Conformal cooling technology is another revolutionary application of 3D printing in the field of casting molds. Mold inserts manufactured through metal 3D printing have cooling runners that can be designed to exactly mimic the surface contours of the casting. This achieves fast, uniform cooling, significantly reducing deformation and shrinkage due to uneven shrinkage, thus dramatically reducing the scrap rate. According to data, molds with follow-through cooling can reduce injection cycle times by as much as 70%, while significantly improving product quality.

From "physical trial and error" to "digital foresight". The core contribution of 3D printing is to transform the traditional foundry model of "trial and error" into "anticipatory manufacturing". It enables foundries to perform numerous iterations in a digital environment in a cost-effective manner, which is a fundamental shift in mindset and business process. This "hybrid manufacturing" model makes 3D printing easier to adopt by traditional foundries and enables the most efficient production. For example, 3D printing can be used to create the most complex and error-prone sand cores, and then combined with sand molds made using traditional methods to "build on the strengths".

Chapter 3: SANTI TECHNOLOGY: A Digital Engine to Empower the Foundry Industry

3.1 Core equipment: "hard power" for casting innovation

As a pioneer and leader in the field of additive manufacturing in China, 3DPTEK provides strong "hard power" support for the foundry industry with its self-developed core equipment.

The company's core product lines are3DP Sand Printerthat highlights its leadership in technology. Flagship devices3DPTEK-J4000With an extra-large molding size of 4,000 x 2,000 x 1,000 mm, it is highly competitive on a global scale. This extra-large size allows large, complex castings to be molded in one piece without the need for splicing, further eliminating potential defects caused by splicing. At the same time, for example

3DPTEK-J1600PlusDevices such as these offer high accuracy of ±0.3 mm and efficient printing speeds, ensuring that superior quality is achieved while producing quickly.

In addition, SANTI Technology'sSLS (Selective Laser Sintering) Equipmentseries, such asLaserCore-6000The machines are also excellent in the field of precision casting. This series of equipment is particularly suitable for the manufacture of wax molds for investment casting, providing a more accurate solution for high-end, fine parts in aerospace, medical and other fields.

It is worth mentioning that SANDI Technology is not only an equipment supplier, but also an expert in material and process solutions. The company has developed more than 20 binders and 30 material formulations, compatible with cast iron, cast steel, aluminum, copper, magnesium and other casting alloys. This ensures that its equipment can be seamlessly integrated into a wide range of casting applications, providing customers with comprehensive technical support.

3.2 All-link services: integrated casting solutions

The competitive advantage of SANDI Technology lies not only in its hardware, but also in the integrated solutions it provides along the whole chain. The company has a strong "Trinity" innovation system - "research institute + post-doctoral workstation + R&D team". This model ensures continuous technology iteration and innovation momentum, and its accumulation of more than 320 patents is a strong proof of its technological leadership.

The company offers a "one-stop" turnkey service from design and 3D printing to casting, machining and inspection. This vertically integrated model greatly simplifies the customer's supply chain management, reduces communication costs and risks, and allows the foundry to focus on its core business.

3.3 Classic Case: Data-Driven Proof of Value

Successful cases are the most persuasive tool to convince potential customers. Through a series of real-world projects, SANDY Technology has quantified the significant business value that 3D printing technology brings.

in order toAutomotive water-cooled motor housingAs an example, this case perfectly demonstrates how the 3DP sand casting process solves the one-piece molding problem of "large size, thin wall, complex spiral cooling channels". 21. The successful application of this technology in the field of new energy vehicles has proved its significant advantages in the production of high-performance, complex structure castings.

On the otherIndustrial pump bodyIn the case of SANDI, SANDI adopted the hybrid manufacturing model of "3DP outer mold + SLS inner core". This complementary strategy shortened the production cycle by 80%, and at the same time improved the dimensional accuracy of the castings to CT7 level, which perfectly proved the powerful effect of the hybrid manufacturing mode.

The joint venture project with Xinxin Foundry provides the strongest business argument. By introducing 3D printing technology, the foundry achieved a turnover increase of 1,35%, doubled its profitability, halved its lead time and reduced its costs by 30%. This series of quantitative data provides irrefutable proof of the return on investment of 3D printing technology in the foundry industry.

The following table visualizes how 3D printing can address the pain points of the foundry industry on both a technical and business value level:

| Casting defects or pain points | Causes and limitations of traditional crafts | 3D Printing Solutions and Value |

| stoma | Poor mold venting; liquid metal entrapped in gas | Uniform, controlled sand permeability; digital simulation optimizes pouring system |

| shrinkage | Uneven cooling; inadequate retraction | Predictive optimization by numerical simulation; uniform cooling by shaped cooling channels |

| Sandwich, Mis-shape | Multi-core assembly, bonding and misalignment; parting face fit errors | One-piece molding of complex sand cores eliminates assembly; no physical parting surfaces required |

| High molding costs | Requires physical molds, highly skilled labor, long lead times | Mold-less production; print directly from CAD files, manufacture on demand |

| Inefficiency and long lead times | Long mold making; repeated trial and error | Reduced cycle time of 80%; rapid iterative design possible; print on demand |

| Increased business value | Low margins and erratic delivery | Turnover up 1,35%, margins doubled; costs down 30% |

Chapter 4: Looking to the future: digitalization and sustainability in the foundry industry

3D printing technology is leading the foundry industry from the traditional "manufacturing" to "smart manufacturing" fundamental transformation. According to the relevant report, the scale of China's additive manufacturing industry continues to grow at a high rate, and in 2022 it will exceed RMB 32 billion. This data clearly shows that digital transformation has become an irreversible industry trend.

In the future, 3D printing will be deeply integrated with artificial intelligence (AI), IoT and other technologies to achieve full automation and intelligent management of production lines. Foundries can use AI algorithms to optimize casting parameters and IoT sensors to monitor the production process in real time, thus further improving yield rates and production efficiency.

In addition, the unique advantages of 3D printing in realizing complex lightweight design will help automotive, aerospace and other downstream industries to improve product performance and reduce energy consumption, which is a perfect fit for the requirements of global sustainable development. 3D printing's on-demand production mode and extremely high material utilization (can be recycled more than 90% unbonded powder), also significantly reduces the generation of waste, for the casting industry to bring the environmentally friendly development path for the foundry industry.

concluding remarks 3D printing is not the end of casting, but its innovator. It gives the traditional foundry industry unprecedented flexibility, efficiency and quality assurance through its two core advantages of "moldless" and "digital". It enables foundries to free themselves from the plight of high scrap rates and enter a new era of greater efficiency, competitiveness and embrace of innovation. For any foundry seeking to stand out in a competitive market, embracing 3D printing technology, represented by SanDi Technology, is no longer an optional choice, but a necessary path to the future.

]]>Eliminating shrinkage holes has always been a complex challenge for foundries and engineers, with traditional methods often relying on experience and adjusting mold design, pouring systems and cooling processes through trial and error . However, with the advent of additive manufacturing technologies, especially industrial-grade sand 3D printing, casting design and production have been revolutionized, providing unprecedented new ways to completely solve shrinkage problems.

1. Root causes of casting shrinkage: geometrical limitations of conventional molds

To understand how 3D printing solves problems, it is first necessary to deeply analyze the pain points of traditional casting. The main reasons for shrinkage formation can be attributed to two things:

- Compensate for shrinkage deficiencies: As a casting solidifies and shrinks, it needs to be constantly replenished with liquid metal through the pouring system and riser. If the replenishment channels are not properly designed or are insufficient, the liquid metal cannot be transported to the areas most in need of replenishment, resulting in the creation of voids. ?

- Uneven solidification: If the cooling rate of different areas of the casting is not consistent, the heat is difficult to effectively disseminate, the formation of hot joints (hot spot). These hot spots are the last solidified areas, when the surrounding metal has solidified, they lack the liquid metal supplement, very easy to form shrinkage holes. ?

In conventional casting, molds and cores are manufactured with physical tools whose geometry is limited by machinability and releaseability. For example, the holes drilled for cooling water paths can only be straight lines. . This makes it difficult for engineers to design complex, curved make-up shrinkage channels or follow-through cooling channels inside the mold to precisely control the solidification process, thus increasing the risk of shrinkage defects The

2. 3D printing solutions: freedom of design to give "life" to molds and dies

The core strengths of industrial sand 3D printers areDesign Freedomcap (a poem)No mold productionIt prints sand molds and cores layer by layer directly from 3D CAD files. . This characteristic radically breaks through the geometric limitations of conventional processes and provides several powerful means of eliminating shrinkage as follows:

Option 1: Optimize the fill and contraction channel, precise infusion

Using 3D printing technology, engineers can design the optimal make-up shrinkage system inside the mold without having to consider machinability.

- Integrated pouring system: Traditionally, the sprue system (including the sprue and riser) has to be fabricated and assembled separately. 3D printing allows the entire sprue system, the filler riser and the mold itself to be printed in one piece. This integrated design ensures a seamless connection and precise alignment of the channels, greatly reducing the risk of shrinkage failure due to assembly errors. ?

- Design of precise filler risers: 3D printing allows the precise design and printing of shrinkage risers above the hot joint areas of the casting, ensuring a constant flow of molten metal to fill the void created by solidification shrinkage. It has been shown that overflow risers above the casting can effectively vent gases, thus reducing porosity defects in the casting. ?

- Eliminate undercutting and complex structural barriers: In traditional processes, complex undercuts and internal passages require multiple cores to be assembled, which not only increases assembly errors, but can also easily lead to dislodged or misaligned cores. 3D printing allows multiple individual cores to be combined into a single, complex, integrated core, eliminating the need for assembly altogether, and improving the accuracy and quality of the casting. ?

Option 2: Conformal cooling for uniform solidification

For the molds themselves, 3D printing can be equally revolutionary. ByConformal cooling(conformal cooling) technology, which allows the design of cooling channels inside the mold that match the surface contour of the casting. The

- Principle: Conventional cooling channels are drilled in straight lines and do not cover all the areas that need to be cooled, resulting in uneven temperatures in the mold . Conformal cooling, on the other hand, uses 3D printing to integrate curved, serpentine cooling waterways into the mold so that they fit snugly on the surface of the casting . ?

- Advantage: This design results in more uniform cooling and significantly reduces the risk of localized overheating of the mold. A more balanced temperature gradient means that the solidification process is more controlled, radically reducing the formation of hot joints and thus preventing shrinkage. It has been demonstrated that the use of a form-following cooling mold reduces the temperature variation during mold cooling to as low as 18°C, thus significantly reducing the risk of casting warpage. ?

Scenario 3: Digital Simulation and Rapid Iteration to Prevent Problems Before They Happen

The digital workflow of 3D printing provides engineers with valuable opportunities for "trial and error" before going into production. The

- Casting simulation software: Engineers can use casting simulation software (e.g. Cimatron) to simulate the flow and solidification of molten metal. If the simulation results show a risk of shrinkage, the mold design can be quickly adjusted, e.g. by changing the location of the sprue or riser, and then tested virtually again. ?

- Rapid prototyping and iteration: If a physical prototype is required, 3D printing can print a mold or core in hours or days. This allows engineers to iterate and validate designs multiple times at a fraction of the cost and speed. This agile development model is unimaginable in traditional casting, which requires expensive mold making and long waiting times. ?

3. Not just eliminating defects, but a leap in efficiency

The use of 3D printing technology to solve the problem of casting shrinkage, bringing not only the improvement of product quality, but also a series of chain of business value:

- Reduce costs: 3D printing significantly reduces production costs by eliminating the expensive physical mold and tooling manufacturing aspects . According to research, 3D printing can save up to 50%-90% compared to traditional methods . ?

- Shorten the delivery time: Mold making time has been reduced from weeks or even months to hours, allowing companies to respond more quickly to market demands . In one case, a company was able to reduce lead times by 9 weeks by using a sand 3D printer. ?

- Reduce scrap rates: The accuracy and consistency of the molds have been greatly improved, reducing casting defects due to human error or mold wear, thus significantly reducing scrap rates. ?

- Simplify the process: Consolidating multiple parts into a single integrated component simplifies complex assembly processes and reduces reliance on highly skilled labor. ?

Conclusion: 3D printing - a "cure" for the foundry industry

Casting shrinkage is not an isolated technical problem, but the traditional casting process in the face of complex design and high-precision requirements of the systematic challenges exposed. Industrial sand 3D printers, with their unique technological advantages, offer a "cure" for the problem at its source. It eliminates the risk of shrinkage by giving engineers unprecedented design freedom, enabling them to build optimized internal structures and cooling systems. The

For the pursuit of excellent quality, efficient production and cost optimization of modern foundry enterprises, 3D printing is no longer dispensable "additional options", but to promote industrial upgrading, in the fierce competition in the market to win the first chance of the key technology. It is not just a piece of equipment, but also to the "digital casting" bridge to the future, so that the former "casting problems" to be solved! The

]]>I. Equipment selection strategy based on casting size

The size of the casting is a central factor in determining the specification of a sand 3D printer, which needs to be selected with a balance between current needs and future developments:

- Statistical analysis of existing casting dimensions

- Enterprises need to comprehensively sort out the past 1-2 years of casting orders, categorized by product type (such as automotive parts, aviation structural components, pumps and valves shells), statistics on the length, width and height of each type of casting size range, drawing size distribution histogram. For example, an automobile foundry statistics found that 60% engine block castings in 300-500mm in length, width 200-350mm, height 150-250mm;

- Identify the "core size range" with the highest percentage and use it as a basis for filtering printers. As in the case above, 3DPTEK's 3DPTEK-J1800(molding size 1800×1200×1000mm) can easily cover most of the engine block sand printing needs, to avoid "small horse-drawn cart" (equipment molding size is too large, waste of equipment space and printing costs) or "too big to use" (equipment) (equipment molding size is not enough to print large castings).

- Considering future business expansion

- Combined with the enterprise's market planning for the next 3-5 years, new product development plan, prejudge the casting size changes that may be involved. If you plan to develop the wind power equipment castings business, you need to investigate in advance the size of wind power hubs, blades and other large castings (wind power hub diameter of up to 3-5 meters), to reserve enough space for equipment upgrades;

- If large castings are only occasionally undertaken, consider 3DPTEK's 3DPTEK-J4000 Ultra-large size printer (maximum molding size 4000×2000×1500mm), or "sand cut block + combined assembly" printing strategy (3DPTEK equipment supports localized printing, which facilitates the operation of the cut block), to reduce the cost of equipment procurement.

- Handling of special size requirements

- For castings with special dimensions such as extra-long, extra-wide, extra-thin, etc. (e.g., elongated shaft castings with an aspect ratio of more than 5:1, thin-walled parts with a thickness of less than 5mm), it is necessary to examine the printing accuracy and stability of the equipment in addition to the molding dimensions. 3DPTEK's bonded injection technology ensures that the molding of special-sized castings is performed with a high degree of precision of ±0.3mm, thus avoiding the scrapping of castings due to deviations in dimensions. avoid scrapping the castings due to dimensional deviation.

Second, suitable for the casting material equipment parameters selection

Different casting materials (e.g. cast iron, cast aluminum, cast steel) have different requirements for sand strength, air permeability and gas generation, which need to be matched with the corresponding equipment parameters and material technology:

- Material properties and sand demand analysis

- Cast iron parts: due to the good fluidity of iron and moderate solidification shrinkage, the strength of the sand mold is required to be high (tensile strength ≥ 0.8MPa) to prevent the sand mold from erosion and breakage during pouring. The high-strength furan resin binder matched with 3DPTEK equipment, together with silica sand, can meet the needs of sand mold printing for cast iron parts;

- Aluminum casting: Aluminum liquid solidification speed is fast, easy to absorb air, the sand type is required to have good air permeability (air permeability value ≥ 150) and low outgassing (outgassing ≤ 15ml/g), to avoid casting porosity defects. 3DPTEK's open-source material process can be adjusted according to the needs of the binder formula, suitable for ceramic sand, zirconia sand and other low outgassing, high air permeability sand, to meet the casting of aluminum casting sand print.

- Material compatibility and parameter adjustment

- The 3DPTEK sand 3D printer supports a wide range of casting sands (including quartz sand, pearl sand, chromite sand, etc.), allowing companies to choose sand materials flexibly according to casting materials and cost considerations. For example, when producing high-end stainless steel castings, zirconium sand (high temperature resistant and chemically stable) is used with 3DPTEK's special binder to improve the sand mold's anti-washout and anti-sticking properties;

- The nozzle parameters (e.g., orifice diameter, spraying frequency) and heating and curing parameters (curing temperature and time) of the equipment need to be precisely adjusted according to the characteristics of the sand material and the type of binder. For example, when using fine-grained quartz sand, it is necessary to reduce the diameter of the spray hole (e.g., from 0.3mm to 0.2mm) and increase the spraying frequency to ensure that the binder evenly covers the sand particles; for thermosetting binder, it is necessary to optimize the heating curing curve (e.g., increase the curing temperature from 150℃ to 180℃, and extend the curing time from 30 seconds to 45 seconds), so as to ensure that the strength of the sand pattern curing.

- New material application and technical support

- As the casting industry's demand for high-performance, lightweight castings increases, new types of sand materials (such as composite sand mixed with metal powders and nano-modified sand) are gradually being applied. 3DPTEK continues to research and develop new material processes that can be customized to meet the needs of enterprises and customize material solutions to help them quickly realize the application of new materials in sand printing.

Comprehensive Advantages of 3DPTEK Sand 3D Printers

- Full-size product matrix: 3DPTEK has a full line of sand 3D printers ranging from 1.6 meters to 4 meters in size, including 3DPTEK-J1600Pro,3DPTEK-J1600Plus,3DPTEK-J1800,3DPTEK-J1800S,3DPTEK-J2500,3DPTEK-J4000 A variety of models, such as to meet the different sizes of enterprises, different sizes of castings printing needs, to avoid enterprises due to the limitations of equipment specifications missed orders.

- open source material processIt supports users to adjust the binder and sand material formula as needed to reduce the material cost 20%-30%. At the same time, it is equipped with high-performance resin binder, curing agent and cleaning agent to ensure the stable quality of sand molding and solve the problems of material selection and process optimization of the enterprise.

- High-precision molding technologyThe company adopts piezoelectric inkjet technology, high-resolution inkjet system, and special binder formula to realize ±0.3mm high-precision printing, which effectively reduces the machining allowance of the castings, improves the quality of the castings and the production efficiency, and is especially suitable for aerospace, automotive and other industries with stringent requirements for precision.

- Flexible area molding without sand boxAs 3DPTEK-J4000 Innovative use of sandbox-free flexible area molding technology, support for local printing, can economically and efficiently realize the manufacture of oversized sand molds, compared with the traditional box printing, the equipment footprint is reduced by more than 30%, and the printing cost is reduced by 15%-20%.

Through the above selection strategy based on casting size and material, combined with the comprehensive advantages of 3DPTEK sand 3D printers, enterprises can accurately match the parameters of the equipment to achieve a high degree of compatibility between equipment performance and production needs, and at the same time improve the quality of castings, reduce production costs and enhance market competitiveness.

]]>工業級蠟模 3D 打印機:2025 年大型鑄造全指南,縮短 80% 周期 + 提升精度方案最先出現在三帝科技股份有限公司。

]]>I. What is an industrial-grade wax 3D printer? Core Definition + Comparison to Traditional Processes

Industrial-grade wax mold 3D printers are based onSelective laser sintering (SLS) TechnologyIt is an industrial machine for the production of high-precision wax molds made of casting wax powder / wax-like powder, which are fused layer by layer and can be used directly for lost wax investment casting. It has significant advantages over the traditional wax molding process and is especially suitable for large casting scenarios (part sizes above 500 mm):

| comparison dimension | Industrial Wax Mold 3D Printer | Traditional wax molding process (handmade / CNC) |

| production cycle | 3-7 days (large wax models) | 2-4 weeks |

| Dimensional accuracy | ±0.1mm | ±0.5-1mm |

| Complex structure realization | Easy printing of internal cooling channels, thin-walled honeycomb structures | Multiple sets of wax molds need to be disassembled and are prone to assembly errors. |

| labor cost | Automated printing, one person can operate multiple machines | Dependence on skilled tradesmen, high labor costs 300% |

| Material utilization | 90% above (unsintered wax powder recyclable) | 60%-70% (cutting / manual waste) |

| Design Iteration | CAD files can be reprinted within a few hours after modification. | Need to remake the mold, long cycle time |

The 4 core benefits of industrial-grade wax mold 3D printers for foundries (solving industry pain points)

1. Reduced cycle time 80% for fast response to order requirements

It takes 3 weeks to make a wax mold of a large automotive engine block using traditional processes, but an industrial-grade 3D printer can do it in just 3 days. An aerospace foundry used LaserCore-5300 to print a wax model of a turbine blade, from design to finished product in 48 hours, shortening 80% compared with the traditional process, and compressing the trial production cycle of a new product from 3 months to 1 month, thus seizing the first opportunity in the market.

2. 5 times higher accuracy and lower casting scrap rate

Industrial-grade wax mold 3D printer has an accuracy of ±0.1mm and surface finish Ra≤1.6μm, which can reduce the casting post-treatment process. Due to the large error of wax mold made by traditional process, the casting scrap rate is more than 15%; while the 3D printed wax mold reduces the scrap rate to below 5%, and a foundry produces large valve castings and reduces the loss of scrap by 800,000 RMB annually.

3. Breaking through structural limitations and realizing difficult casting

No need to consider "mold release" issues, allowing for designs not possible with conventional processes, especially for high-end manufacturing:

- Aerospace:Multi-layer cooling channels inside the turbine blades(The traditional process requires 5 sets of wax molds to be disassembled, while 3D printing molds the mold in one go, with no assembly errors);

- Cars:Engine block integrated runners(Reduced post-drilling process and increased fluid efficiency by 10%);

- Heavy machinery:Thin-walled honeycomb structure for large shells(Wall thickness as low as 2mm, weight reduction 20%, strength increase 15%).

4. Long-term cost reductions 40%, offsetting equipment investment

Despite the high initial investment ($50,000+) for an industrial-grade wax-molded 3D printer, the cost advantage is significant when calculated over the full lifecycle:

- Eliminate mold costs: Traditional large CNC wax mold mold costs over 200,000 yuan, 3D printing can be completely eliminated;

- Reduced labor costs: 1 person can operate 3 machines, reducing 80% labor compared to the traditional process;

- Reduction of scrap loss: precision improvement has reduced the casting scrap rate from 15% to 5%, saving more than 500,000 yuan in material cost per year.

Industrial Wax Mold 3D Printing Workflow: 6 Steps from Design to Wax Mold (for Large Casting)

The industrial wax 3D printing process is highly automated and does not require complex human intervention. The core steps are as follows (for example, wax molding of a large turbine blade):

- Digital Design and OptimizationThe 3D model of the wax mold is constructed in SolidWorks/AutoCAD, the shrinkage is reserved according to the casting metal properties (e.g. steel needs to be enlarged from 1%-2%), and the structure of the sprue and the vent is designed and exported as an STL format file;

- Device parameter settingLoad casting wax powder into a printer (e.g. LaserCore-6000) and set the parameters: layer thickness 0.08-0.35mm, laser power 55-300W, molding rate 80-300cm3/h to ensure that it is suitable for large wax models;

- automated printingAfter the equipment is started, the laser sinter the wax powder layer by layer according to the slicing trajectory. It takes 10-20 hours for a large wax model (e.g. 1050×1050×650mm) to be printed unattended at night without human intervention;

- Cleaning up after printingAfter the wax mold is completed, remove it from the molding chamber, blow off the excess wax powder on the surface with compressed air (this wax powder can be recycled directly), and inspect the wax mold for holes and cracks (the defect rate of 3D printed wax molds is less than 1%);

- Wax mold assembly (mass production)If batch casting is required, individual wax molds are attached to a "wax tree" to improve pouring efficiency;

- Suitable for lost wax castingThe wax mold is immersed in ceramic slurry to form a high-temperature-resistant ceramic shell, which is then burned in a 700-1000°C kiln to remove the wax mold (the ash content of the 3D printing wax mold is <0.1%, and the combustion is complete with no residue), and then the metal can be poured in.

How to choose industrial-grade wax 3D printers for foundries? 4 core selection criteria

1. Prioritizing molding space: adapting to the needs of large-scale casting

Large casting parts (such as automotive engine blocks, aerospace frames) with dimensions of 500-1000mm, need to choose the molding space ≥ 500 × 500 × 500mm model:

- For small and medium-sized foundries (part sizes 500-700mm): A model with a molding space of 700×700×500mm (e.g. LaserCore-5300) is available;

- Large foundries (part size 700-1000mm): We recommend a model with a molding space of 1050 x 1050 x 650mm (e.g. LaserCore-6000).

2. Technology Type Lock SLS: Ensuring strength and precision of wax molds

SLS technology sintered wax powder by laser, the wax molds have high density (≥0.98g/cm3) and high strength (flexural strength ≥15MPa), which can withstand the external force during ceramic paste coating and handling to avoid deformation. Wax molds made by other technologies (e.g. FDM) have low strength, are easily damaged and are not suitable for large-scale casting.

3. Focus on core parameters: accuracy, speed and material compatibility

- accurate: Choose a ±0.1mm model to ensure casting dimensions are met and to minimize post-processing;

- Molding rateThe priority is given to models with more than 200 cm3/h (e.g. AFS LaserCore-6000 up to 300 cm3/h) to increase the efficiency of the production of large wax molds;

- Material compatibility: A wide range of casting waxes (e.g. low ash casting waxes, high temperature waxes) are required to support the casting of different alloys (aluminum alloys, steel, titanium alloys).

4. Software and services: making the transition less difficult

- The software must be compatible with the main CAD formats (STL/OBJ) and come with casting simulation (optimization of the structure of the wax model and reduction of defects);

- Service providers need to provide full-process support: free operator training (to ensure that the operation is mastered within 3 days), equipment installation and commissioning, 24-hour after-sales response (domestic door-to-door service ≤ 24 hours).

V. 2025 industrial-grade wax mold 3D printer popular models recommended (suitable for different casting needs)

Based on industry feedback and actual application cases, the following 3 models in 2025 are outstanding in the large casting field, covering entry to high-end scenarios:

| models | Molding space (mm) | Type of technology | accurate | Molding rate | Applicable Scenarios | Core Advantages |

| AFS-500 (entry level) | 500 x 500 x 500 | SLS | ±0.1mm | 80-150cm3/h | Industrial tools, small and medium-sized castings (up to 500mm) | Cost-effective, low power consumption (15KW), suitable for small and medium-sized foundry trial production |

| LaserCore-5300 (mid- to high-end) | 700 x 700 x 500 | SLS | ±0.1mm | 150-250cm3/h | Aerospace turbine blades, automotive parts (500-700mm) | Rapid iteration, stable accuracy, suitable for multi-material printing |

| LaserCore-6000 (high-end) | 1050 x 1050 x 650 | SLS | ±0.1mm | 250-300cm3/h | Large automotive engine blocks, aerospace frames (700-1000mm) | Extra large molding space, high efficiency of mass production, suitable for high production foundries |

Model highlights analysis

- AFS-500Low entry cost, easy to operate, 1 person can manage multiple machines, suitable for small and medium foundries trying 3D printing for the first time, for small and medium-sized wax molds such as industrial tools, valves, and so on;

- LaserCore-5300The wax molds of turbine blades are widely used in the aerospace industry. The wax molds have a high surface finish and do not need to be polished, increasing the yield of the castings to more than 95%;

- LaserCore-6000The machine is one of the few in China that can print 1050mm wax models, and can nest 20 small and medium-sized wax models (e.g., automotive parts) in a single run, which increases the utilization rate of the machine by 60%.

Industrial Wax Mold 3D Printing Common Problems + Expert Solutions

1. High initial investment in equipment? -- Phased investment reduces risk

Small and medium-sized foundries can purchase entry-level models (e.g., AFS-500) for wax molding of high value-added parts (e.g., precision valves), quickly recoup their costs through high-margin orders, and then upgrade to higher-end models after 1-2 years.

2. Incomplete burning of wax molds leading to defective castings? -- Optimization of sintering and firing parameters

- When printing: Adjust the laser power (55-80W) to ensure that the sintered density of the wax mold is ≥0.98g/cm3 and to reduce the internal porosity;

- Firing: gradually increase the kiln temperature from 700°C to 1000°C and hold for 2-3 hours to ensure complete vaporization of the wax model (can be verified by the change in weight of the ceramic shell).

3. Wax powder recycling is difficult, material waste? -- Configure automated recycling system

By choosing the wax powder recycling equipment with automatic screening and drying function, the unsintered wax powder can be reused directly after treatment, and the material utilization rate is increased from 90% to more than 95%, which saves 200,000 yuan of material cost per year.

4. Unskilled team operation, affecting productivity? -- Give preference to "equipment + training" as an all-in-one service.

Choose a service provider that provides free training (such as AFS brand), 1 to 1 teaching operators to master the daily operation of the equipment, troubleshooting, to ensure the normal operation of the equipment.

VII. Conclusion: Industrial-grade Wax Mold 3D Printer, "Must-have Equipment" for Foundry Transformation